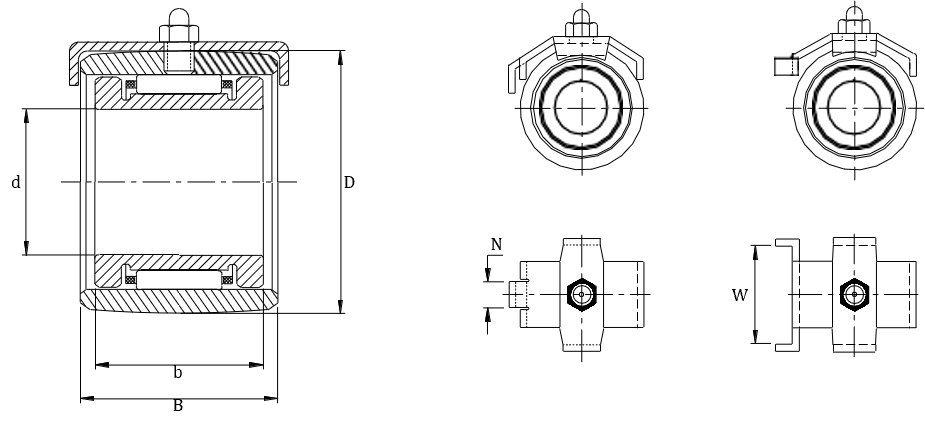

PSI Spinning Bottom Roller Bearings. Textile Bottom roller bearings, Ring frame Bottom Roller Bearings provides a comprehensive solution for all your textile machine needs, offering high-quality bottom roller bearings tailored to specific applications. PSI Bottom Roller Bearings are a highly specialized type of needle roller bearing specifically engineered for the demanding environment of textile machinery. Unlike standard bearings, their design incorporates features such as a high radial load capacity to handle the significant forces of the drafting process, a compact form factor to fit within tight machine spaces, and a robust sealed construction to protect against contamination from cotton fibers and dust. A key feature is the crowned outer ring, which allows the bearing to tolerate minor misalignments, ensuring smooth and consistent rotation of the fluted rollers at high speeds. This precision and durability are crucial for the production of uniform, high-quality yarn, making these bearings an essential component in ring spinning frames, roving frames, and other textile machines where reliability and performance directly impact the final product.