Engineered Excellence in Bearing Manufacturing

Using advanced machinery, PSI manufactures precision bearings for various sectors—including industrial, textile, cotton ginning, and automobile machinery—highlighting their essential role in machine development.

"For the manufacture of high-quality bearings, our facility is equipped with a comprehensive range of advanced machinery, including: The best fully automatic grinding units that ensure high-speed inner and outer grinding with equal dimensional precision. A suite of CNC machining centers: CNC Lathes, CNC Turning Machines, CNC Milling Machines, and versatile VMC machines. Specialized equipment such as CNC Laser Machines, CNC Pulse Cutting Machines, Knife Grinding Machines, and CNC Hobbing Machines. Dedicated machines for component integrity, including a Material Hardening Machine and C.N.C. polishing machines for superior surface finish."

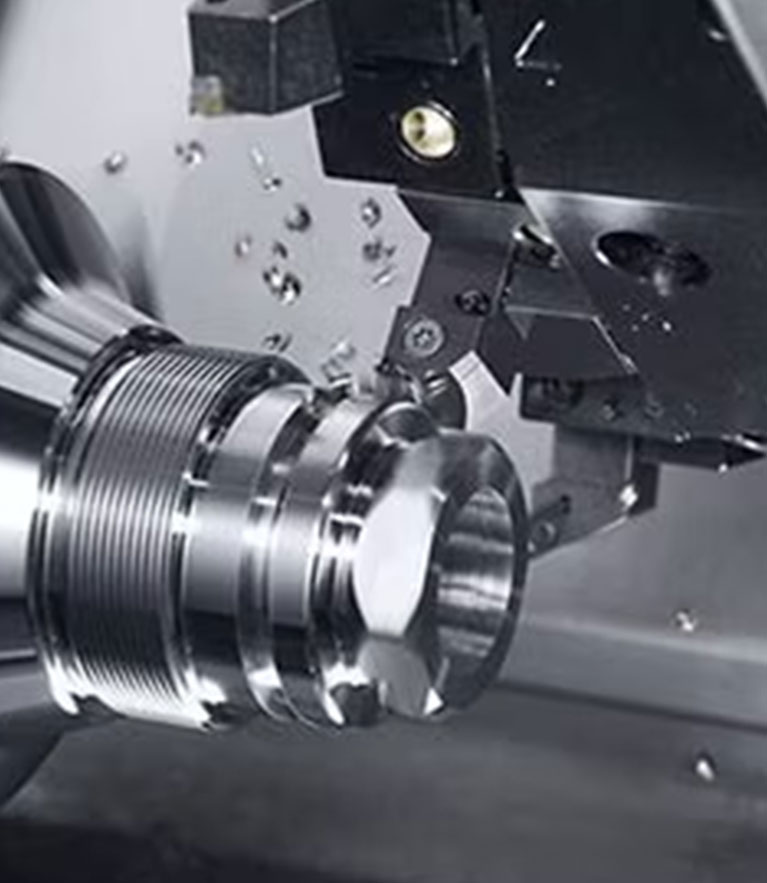

CNC TURNING & LATHE MACHINE : Used for turning the basic shape of the inner and outer races.

Operated with Computer Numerical Control (CNC) systems and provided with precise design instructions, CNC Lathes are machine tools where the material or part is clamped and rotated by the main spindle, while the cutting tool that work on the material, is mounted and moved in various axis.

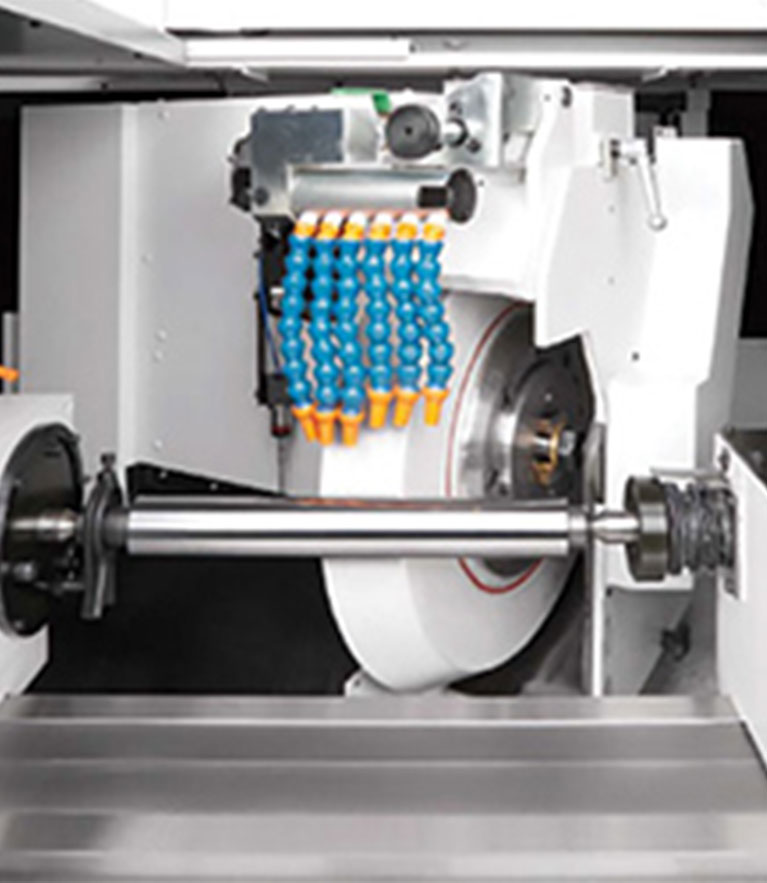

CNC Vertical Rolling Machine : Form the rough rings from heated steel billets. .

The CNC Vertical Rolling Machine (or Vertical Ring Rolling Mill) is a vital piece of advanced machinery in the bearing industry, primarily used during the forging phase to create the high-strength inner and outer bearing rings. This computer-controlled process takes a heated steel blank and rolls it under high pressure to reduce wall thickness and increase diameter, which is essential for optimizing the steel's internal grain flow; this structural enhancement yields rings with superior resistance to fatigue and significantly longer operational life under heavy loads. By creating a near-net-shape ring with high material density and uniform structure, the machine substantially reduces raw material waste and minimizes the intensive precision grinding required in later stages, directly contributing to the final high quality and cost-effectiveness of the precision bearings.

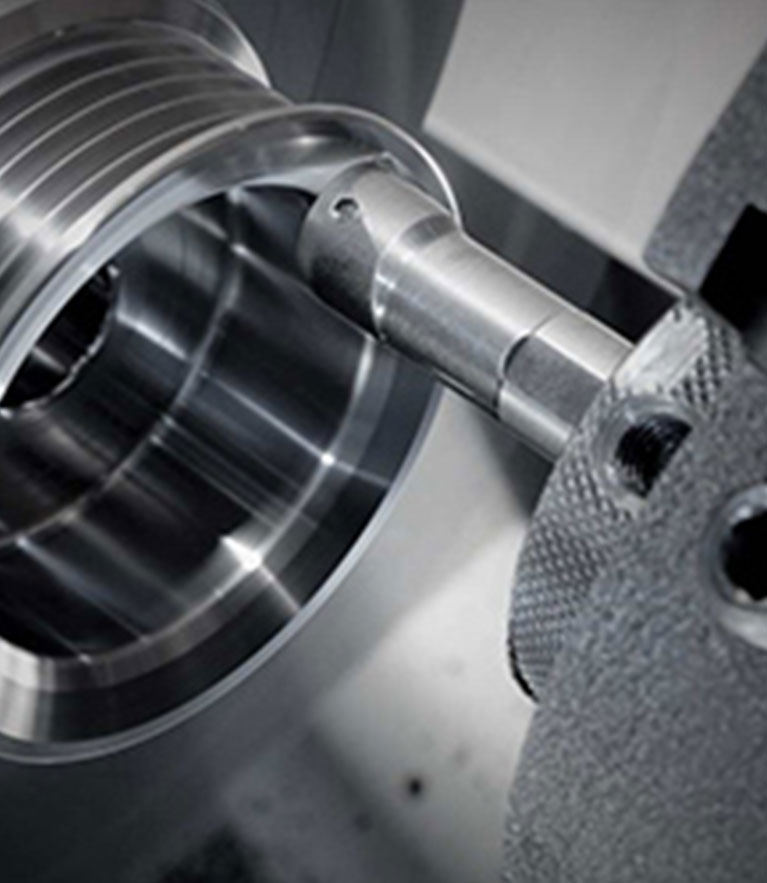

CNC GRINDING MACHINE :

These machines precisely grind the rings and rollers to achieve the exact dimensions and smooth surfaces needed for bearing operation. Grinding for rings, collar, and bearings or more products. CNC grinding machine is a precision performance tool that uses a rotating wheel to cut material away from metal. Machining can be a tough job when done by hand, and the CNC process allows machining to be completed with a high level of computerized control performance.

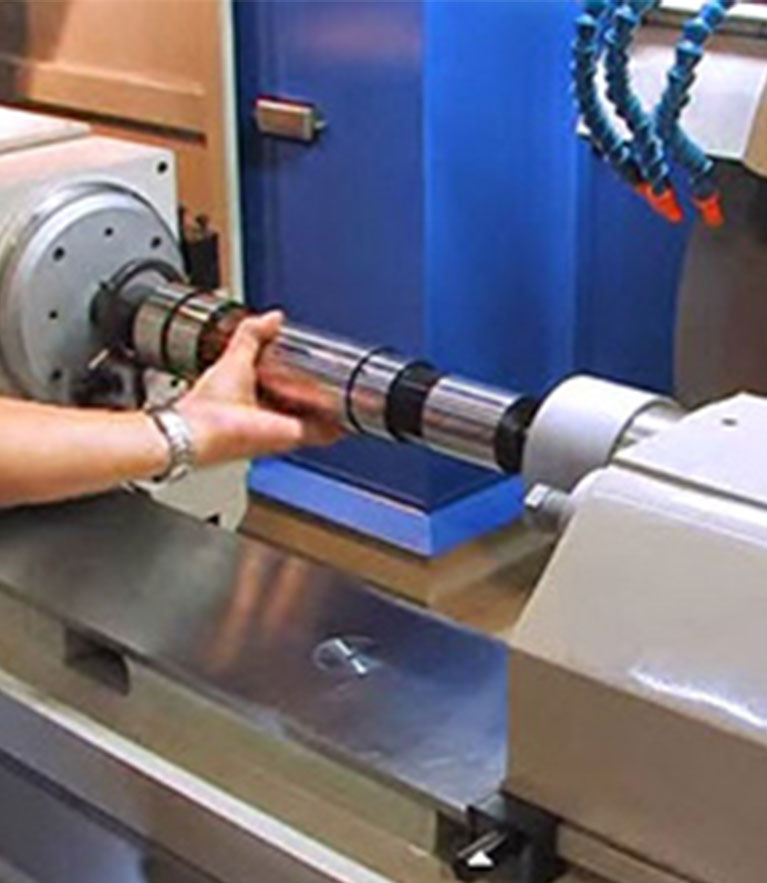

Honing and Lapping Machines:

For superfinishing the bearing surfaces, which involves using abrasive slurries or pastes to remove microscopic imperfections after grinding.

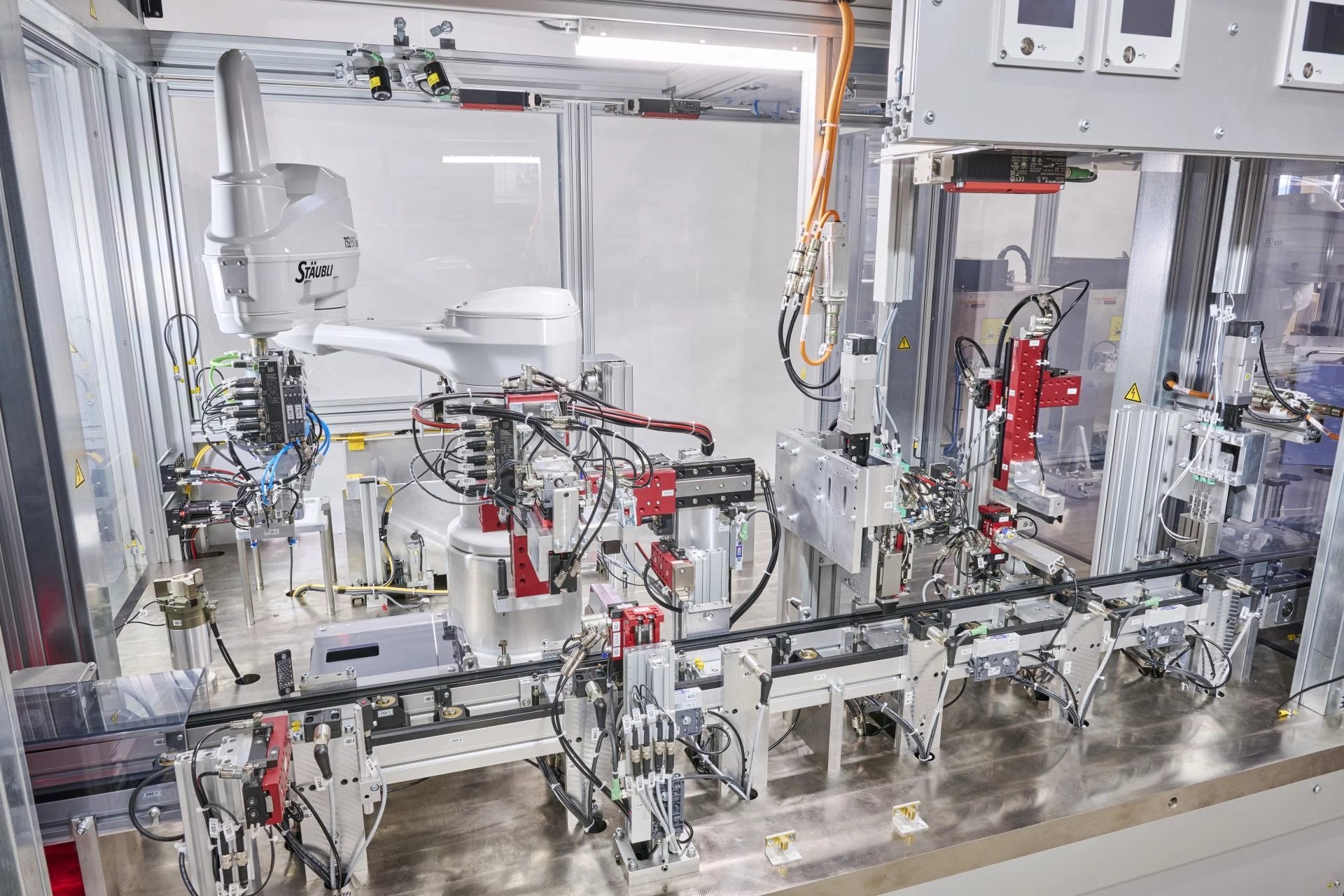

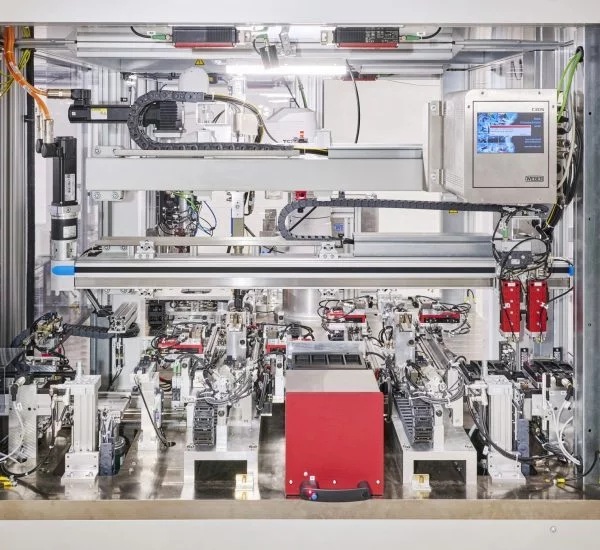

Automated Assembly Lines:

Robotic systems, conveyors, and vision systems are used to efficiently assemble all the bearing components into a complete unit.