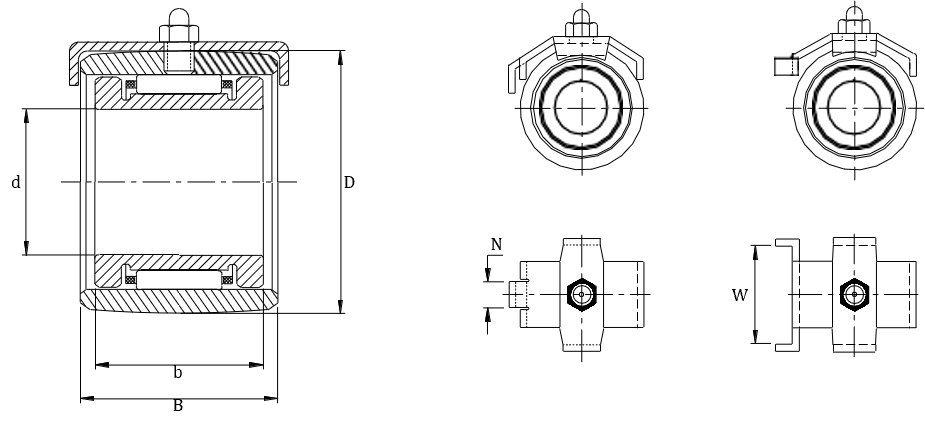

Bottom Roller Bearings PSI-2816 (24) 1323

High-speed, single-row bottom roller bearings are structurally analogous to a pair of single-row bearings mounted back-to-back, yet they occupy a significantly smaller axial footprint. These bearings are engineered for sustained high-speed operation and excel at accommodating substantial axial loads from either direction, making them uniquely suitable for applications where other bearings might fail.

- "Structurally analogous to" is more precise than "correspond to in their design and operation." It clearly states the similarity without being wordy.

- "Engineered for sustained high-speed operation" is a more powerful and professional way to say "can operate at high speeds." It implies deliberate design.

- Tolerances: The bottom roller and the corresponding bearing must have precise tolerances. If the roller's outer diameter or the bearing's inner diameter is slightly off, it will cause either a loose fit (which can lead to vibration and wear) or a tight fit (which makes installation difficult and can damage components).

- Surface Finish: A smooth, non-porous surface finish on both the roller and the bearing is crucial. Rough surfaces increase friction and can prevent the components from sliding together easily.

- Lubrication: A thin film of appropriate lubricant can significantly reduce friction during the fitting process. This is especially helpful for a press or interference fit.