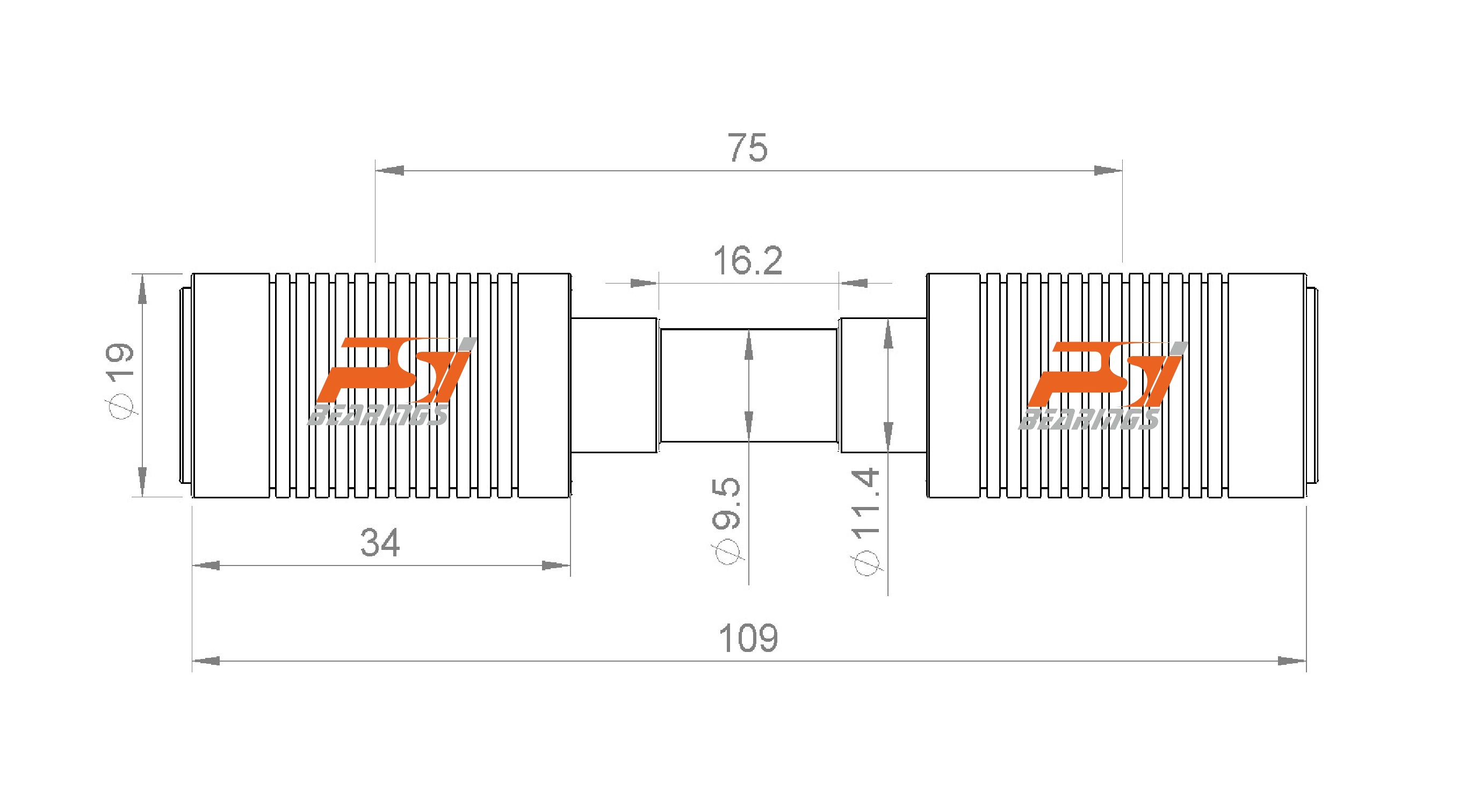

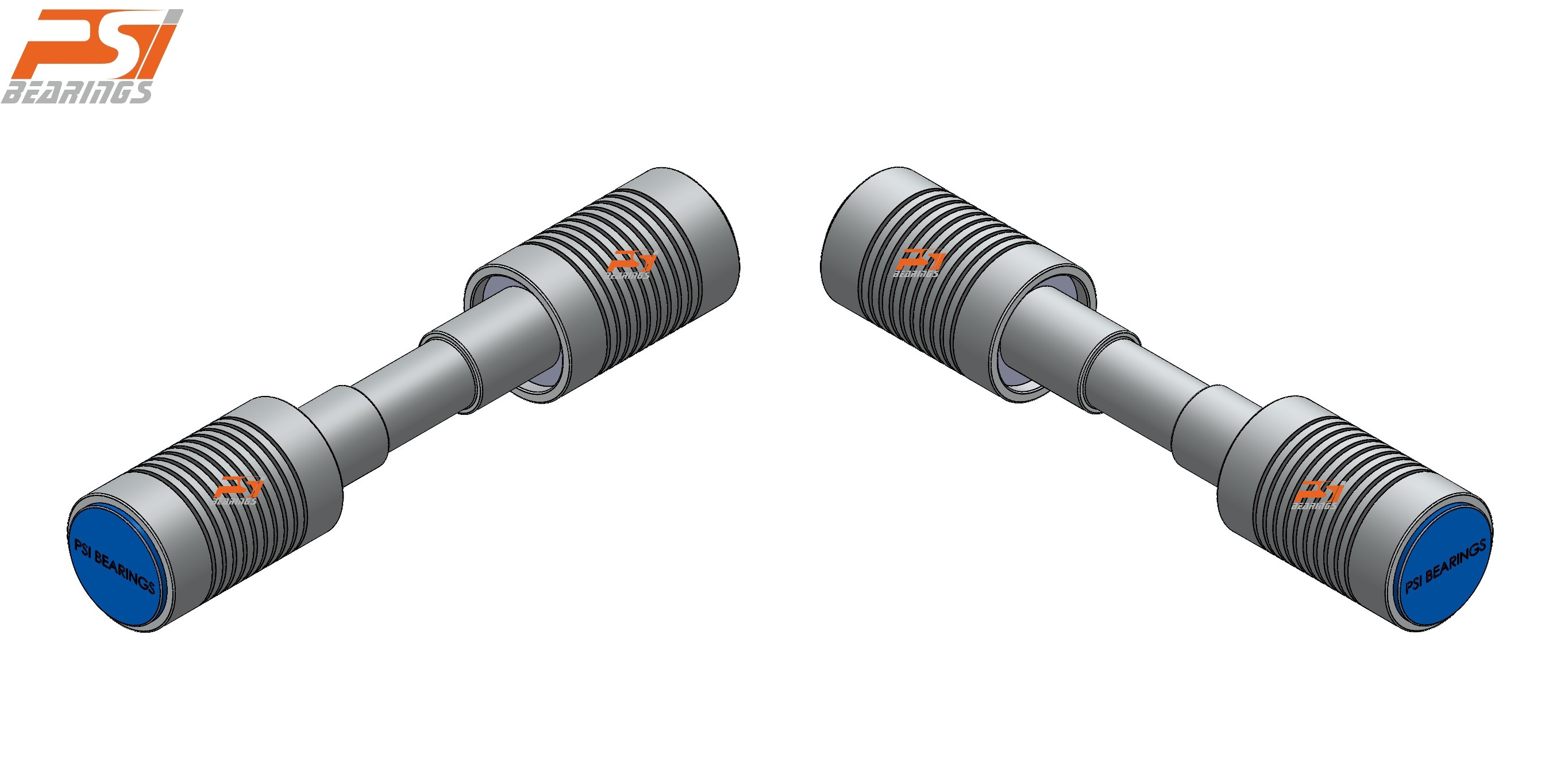

Top Roller LP-1002-1248-601

Textile top rollers are critical components in spinning machinery, primarily found in drafting systems of machines like ring frames, speed frames (roving frames), draw frames, and combers. Their main purpose is to precisely control the fibers during the drafting process to ensure high-quality and even yarn.

- A typical anti-friction top roller is a precision-engineered component with several parts:

- Shell/Arbour: The core component, often made of hardened alloy steel, ground to high precision

- Anti-Friction Bearings: They are typically fitted with double-row ball bearings to ensure smooth and silent running with minimal friction, even at high speeds and under high load capacity.

- Lubrication and Sealing: They are usually injected with a special long-life grease and fitted with seals to prevent lubricant leakage and contamination ingress.

- Cot (Covering): The surface that comes into contact with the fibers is covered with a rubber cot (or sometimes synthetic materials).

- Cot Material: Various rubber or synthetic compounds (like NBRs, CSMs, or specialized blends) are used, with properties like specific hardness (Shore A), chemical resistance, and anti-static properties tailored for different fiber types (cotton, synthetic, wool) and processes.

- Cot Hardness: Hardness ranges are common, such as 60 Shore A to 85 Shore A, depending on the machine and material being processed.

- Cot Features: Some cots can feature special surface designs, like spiral grooves, to help remove trash particles